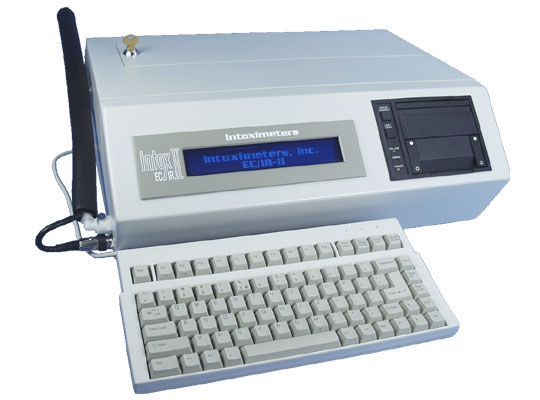

Intox EC/IR

The Intox EC/IR and Intox EC/IR II are alcohol breath test devices manufactured by Intoximeters, Inc. in St. Louis, Missouri. EC stands for electro-chemical and IR stands for infra-red. These are two very different methods of measuring ethanol. The infra-red method relies on the absorption of infra-red light by alcohol in the sample chamber which is noted by a detector at the opposite end of the chamber. In the Intox EC/IR, the infra-red detector does not provide a quantitative measurement of the amount of ethanol in the sample. Rather the breath sample first passes through the infra-red portion of the device, which monitors the ethanol content at 3.45 microns and carbon dioxide at 4.26 microns. Based on these measurements, satisfaction of the minimum volume and flow requirements, and/or slope detection, the device determines when during the exhalation the fuel cell analysis should occur.

The electro-chemical, or fuel cell method, converts fuel, in this case ethanol, and an oxidant, here oxygen, into acetic acid and water. The process creates a direct electrical current proportional to the concentration of alcohol in the sample, which can be measured. The alcohol fuel cell is made up of an inert porous substance, about the size of a button, covered on both sides by platinum, known as platinum black. The porous layer is filled with an acidic electrolyte solution. There are electrical connections to the upper and lower platinum black surfaces. All of these are contained in a small sample chamber, into which the breath passes through an inlet.

When a breath sample passes through the chamber, the alcohol molecules on the upper surface of the platinum black and oxygen are converted into acetic acid and water, a process which frees two electrons per molecule. An electric current is created between the upper and lower platinum black which is thus proportional to the concentration of alcohol in the breath sample. By measuring the current, and applying the calculations dictated by the algorithm in the device, a reading for the concentration of alcohol in the sample in grams of alcohol per 210 liters of breath is given.

Each jurisdiction determines what specific features it desires, such as: the testing sequence, flow rate, the minimum breath volume required before fuel cell analysis occurs, whether to engage radio frequency interference (RFI) detection, or mouth alcohol detection. For example, Maryland has opted for a test sequence involving a .08 reference solution check, both before and after two subject sample tests, all separated by blank checks. Maryland has RFI shielding, but no RFI detection. Mouth alcohol detection is turned on. If two samples are more than .02 apart, or if there is insufficient breath, the device automatically requests a third test.

The EC/IR can be set up to accept either a dry gas or wet bath simulator. Maryland uses wet bath. The wet bath alcohol reference solution, also called the simulator solution, is contained in a jar and is connected to the instrument by a series of tubes. It is supposed to produce a reading of .08 plus or minus .008 at a solution temperature of 34° centigrade. Both the thermometer in the simulator, as well as the solution, should be traceable to NIST. Traceable to NIST or the National Institute of Standards and Technology is a term of art that implies a series of comparisons traceable back to a standard approved by NIST. In City of Seattle v. Clark-Munoz, the Washington Supreme Court held that failure to trace simulator thermometers to NIST required exclusion of the breath test.

The EC/IR comes with a computer keyboard attached that controls its operation. The operator can type their name, the subject's and arresting officer's names, and the time the observation period has begun. Certain keys control other functions, such as printing out information that may be useful in reviewing the operation of the EC/IR. For example, pressing the F1 key prints out a list of commands. The shift and F5 keys, when pressed together will print out all of the calibration tests or all of the accuracy checks in the instrument's memory. The F11 key prints out numerous factory settings and can be programmed to display or omit readings desired by the purchaser. Rankin Forrester, Chief Executive Officer of Intoximeters, Inc., wrote in December 2007 with respect to the F11 print out:

With regard to questions about the F11 printout settings file on the EC/IR used in Maryland, I have the following comments.

- First, the F11 setting is pass-code protected because it was intended to be used only for factory level diagnostics. The settings included in this file are a listing of the way that the instrument is setup at the moment in time that the printout or upload is performed. The listing does not necessarily reflect the settings of the instrument at any other point in time.

- The list includes several types of information. Some of the settings are intended to be read only data (i.e. instrument serial number). These include settings that are defined by the manufacturer and some are defined by the requirements of the MD alcohol testing program (Accuracy Tolerances, Memory Management Technique, Number of Reported Digits). Other settings included in the list are intended such that the individual user can adjust them as required by their protocol (printer type, location). Finally, some of the settings indicate current calibrated values of certain analytical systems in the instrument or are a counter that indicates things like the number of tests currently stored on the instrument.

- This combined set of data offers a snapshot about the particular instrument at a particular point in time that could [be] helpful to a technician who is responsible for diagnosing the condition of an instrument.

The F11 printout from Maryland EC/IRs show that the minimum volume is 1500 milliliters of breath, that mouth alcohol detection is on, and that blank masking is set to .003. The F11 also reports fuel cell gain, which may indicate whether the fuel cell has neared or reached the end of its life span of about three to five years.

There are a number of manuals that describe the operation of the EC/IR. Some of these manuals are state specific. There is an Operator's Manual, a Supervisor's Manual, and an Administrator's Manual. Each manual contains progressively more information depending on the level of training of the technician.

The Intox EC/IR comes with a modem that allows the uploading and monitoring of data by a remote computer. In Maryland, every evidential test run on every EC/IR in the state are uploaded to a computer at the Chemical Test for Alcohol Unit (CTAU) located at the State Police Headquarters in Pikesville, Maryland. Review of the downloaded data can reveal errors in the operation of the EC/IR which may be relevant to the accuracy or reliability of a given test. Error messages included in the downloaded data include: baseline errors, where the fuel cell and infrared measurements do not match; high blank errors; and accuracy check errors, where the alcohol reference solution readings are outside of established parameters. Numerous other errors may be seen by reviewing downloaded data, which may be retrieved in a digital format for entry into a Microsoft Excel spreadsheet, or printed by means of software used by Intoximeters, Inc., IntoxNet, and generated into a report. This information can indicate whether the instrument used in a particular defendant's case had any problems and whether the problems were resolved or left unresolved in a way that is relevant to the integrity of the defendant's test. Both unresolved problems occurring prior to the defendant's test and problems first noticed after the defendant's test may be relevant to the reliability of the defendant's test.

The EC/IR, now called EC/IR I, has been replaced by the EC/IR II. In a letter dated July 6, 2006, M.R. Forrester, Chairman of Intoximeters, Inc., wrote the following about the newer EC/IR II:

- One of the main reasons the EC/IR II was developed was certain parts of the EC/IR I were becoming obsolete, which made them harder to find and more expensive to replace.

- The primary difference concerns the Microprocessor on the motherboard and the case set. The analytical module in the EC/IR II is very similar to the one used in the EC/IR I in that we are using the same Fuel Cell sensor and sampling system. The microprocessor change is necessary because the EC/IR I microprocessor has been made obsolete since it is a state of the art device, which works at a far higher processor speed.

Below is a list of some of the differences between the two instruments:

| Feature | EC/IR I | EC/IR II |

|---|---|---|

| Microprocessor | 2 x 8 bit processor @ 8 MHZ each | 1 x 16 bit processor at 25 MHZ |

| Program Memory | 272 KB Flash | 896 KB Flash |

| Display | Fixed-font VFD display – limited special characters | Graphic VFD display – True-Type (PC) fonts. Fonts stored in program memory |

| Printer | Printrex printer – text mode only – limited special characters | Printrex printer – graphic mode. Printout will look exactly like display |

| Modem | 33.6 kbps modem – limited 9600 bps due to hardware limitations | Pre-FCC approved modem, but may be limited to 28 kbps by phone line conditions |

| Purge Fan | Purge fan with low flow rate – causing multiple purge cycles | New purge fan with higher flow, which is capable of opening stuck mouthpiece |

| Case Set | Custom Design + off-the-shelf hybrid, RF immunity is adequate | Custom design for lower cost, higher RF immunity, and protection from vendor obsolescence. Better sample exhaust arrangement. |

As often occurs with technological advances, the shortcomings of old technology are highlighted by the developments of new technology. For example, the higher flow of the new purge fan "is capable of opening [a] stuck mouthpiece." The implication here is that the mouthpiece on occasion can get stuck, resulting in the machine recording insufficient breath. Additionally, the case set notes that there is higher "R[adio][]F[requency] immunity." Although there is a claim that "RF immunity is adequate" in the EC/IR I, the need for higher RF immunity in the EC/IR II suggests otherwise.

Practice tips and commentary

Another issue that comes up with respect to the EC/IR is the lack of availability of training to third parties such as defense experts and lawyers. Intoximeters, Inc. is extremely stingy in making the EC/IR available for purchase and testing to potential adversaries in court, and to date, only a handful of defense experts and lawyers have been allowed to purchase and train on the EC/IR. Even when defense lawyers and experts have been allowed to purchase and train on an EC/IR it is not likely to be on an EC/IR with the same software and set up as the one sold the states for use in criminal prosecution. Rather, the few lawyers and experts allowed to purchase and train on EC/IRs have been able to access EC/IRs that are distributed to employers for testing at the workplace, known as DOT or Department of Transportation machines. These two facts, the prohibition of purchase and training, to most defense lawyers and experts, and the restriction to DOT setup EC/IRs for the few who have been able to purchase and train on the EC/IR, allows state experts to claim that their knowledge of the device is superior to any defense expert. The prohibitions and restrictions on training raise serious due process concerns.

In State v. Chun, the New Jersey Supreme Court held that such training must be made available to defense lawyers and experts. The court said:

The Special Master also recommended that the State provide Alcotest training for defense attorneys and their experts similar to that provided for operators and coordinators. The State, understandably, objected to this recommendation and urges us to reject it. Although we reject it in part, defense attorneys should not be left without any means of learning about the device or its operation. Rather, we deem it to be in the interests of justice that some form of training be made available to defense attorneys to enable them to better prepare to represent their clients. However, we agree that the State should not be burdened with this responsibility. We therefore direct that Draeger make Alcotest training, substantially similar to that provided to Alcotest operators and coordinators, available to licensed New Jersey attorneys and their designated experts. The training shall be offered at regular intervals and at locations within the State of New Jersey, at a reasonable cost to those who attend.

The Supreme Court, in California v. Trombetta, stated that a defendant in a criminal case must have a fair opportunity to meet scientific evidence offered against him by the State. In order for a defendant to truly be able to examine, interpret and contest the evidence offered by the State, courts must liberally allow discovery and enforce subpoenas directed at providing equal access to the information used by prosecutors and police.

Virtual Forensic Library

Virtual Forensic Library